Aerojet Rocketdyne has signed a Space Act Agreement with NASA in Alabama to design and build a key rocket engine part using additive manufacturing or 3D printing. The company opened a big new rocket propulsion Advanced Manufacturing Facility in north Huntsville earlier this year.

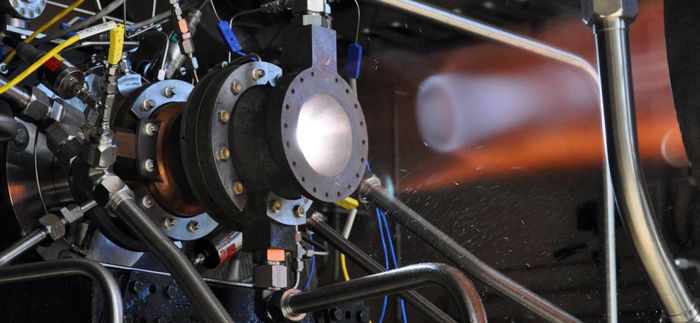

The rocket piece the company plans to build for NASA is a lightweight engine thrust chamber assembly. That’s the business end of the engine where fuels combine, ignite and channel out the bottom to produce thrust.

The goal of the project is twofold. NASA wants to cut the cost of building rocket engine parts, and Aerojet and NASA want “scalable” rocket parts that can be made quickly and made larger or smaller for space craft from large boosters to small lunar landers. “As we look to the future of space exploration, efficiency and scalability will be key, which is why we are excited to work with NASA on this innovative thrust chamber for rocket engines,” Aerojet Rocketdyne CEO and President Eileen Drake said in a statement. “The technology we develop will leverage the most advanced additive manufacturing techniques and materials to help provide efficient and safe transportation to and through space.”

Drake was in Alabama in June to officially open Aerojet Rocketdyne’s two new facilities: a 136,000-square-foot advanced manufacturing facility and a new 122,000-square-foot Defense Headquarters building aimed a winning more defense contracts at Redstone Arsenal. “Huntsville is a great place to build a future, and that’s what we’re doing with our expansion here,” Rocketdyne CEO Eileen Drake said in Huntsville then.